DuPont Shift schedule is an application used by DuPont employees. The program helps workers to manage their daily work schedule and their personal life in a systematic manner. It has several advanced features which allow the user to enter information about their daily work and personal life and then it will generate a report. This report can be used for planning and forecasting purposes.

The DuPont Shift schedule was introduced in the year 1971. The name of the program was inspired by the need of a system which could manage all the shifts of the DuPont workforce. The system was designed for all the departments of the DuPont Company including the chemical plants, textile mills, pharmaceuticals, power production, metallurgy, aerospace and industrial automation, rubber, plastic, rubber product development, etc. Later, the program was extended to include all the departments of the business and was called as DuPont Shift schedule. Later on, the extension was made to all the departments of the business and the name of the program was changed to DuPont Shift schedule Latin.

What Is The DuPont Shift Schedule?

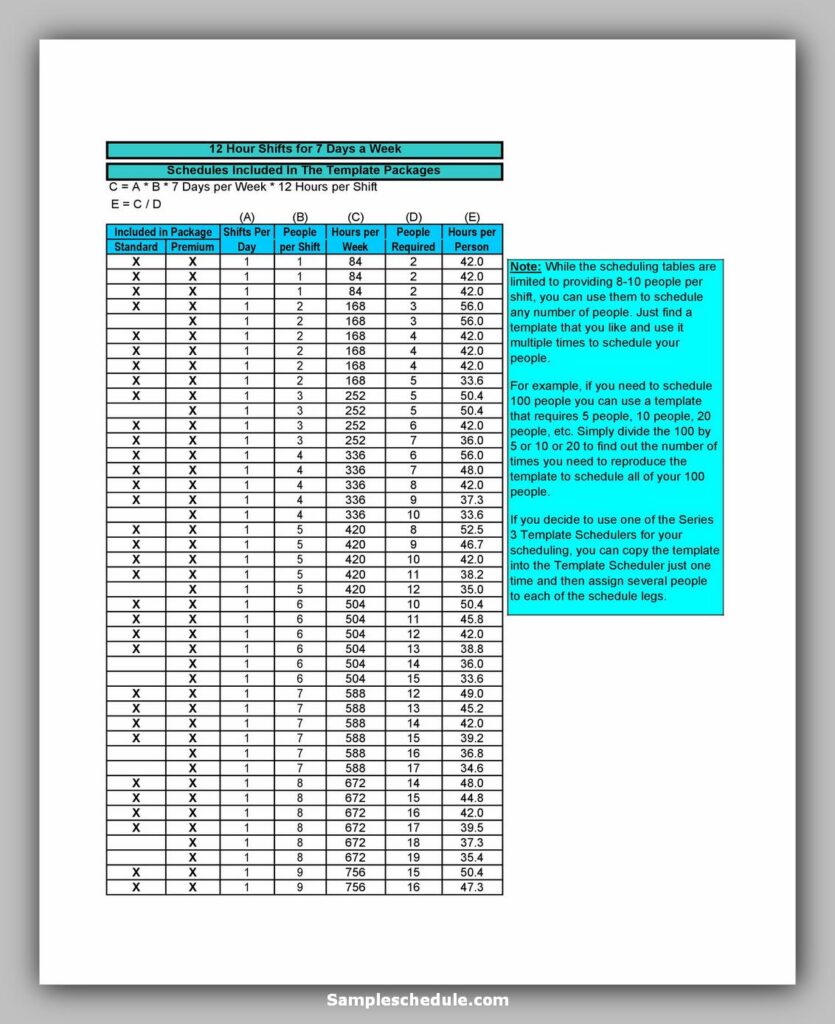

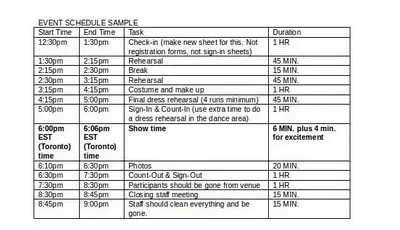

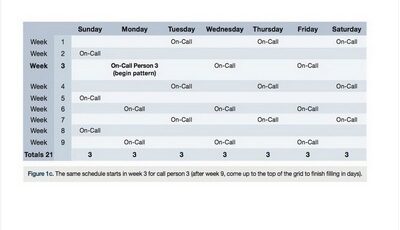

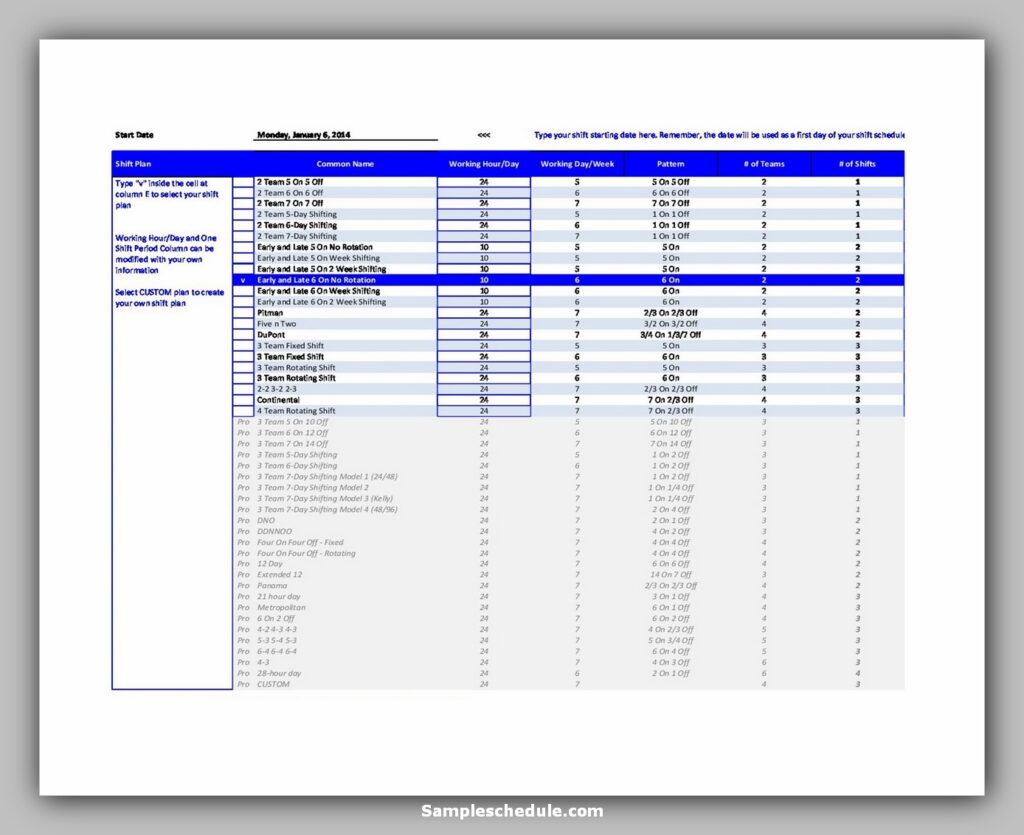

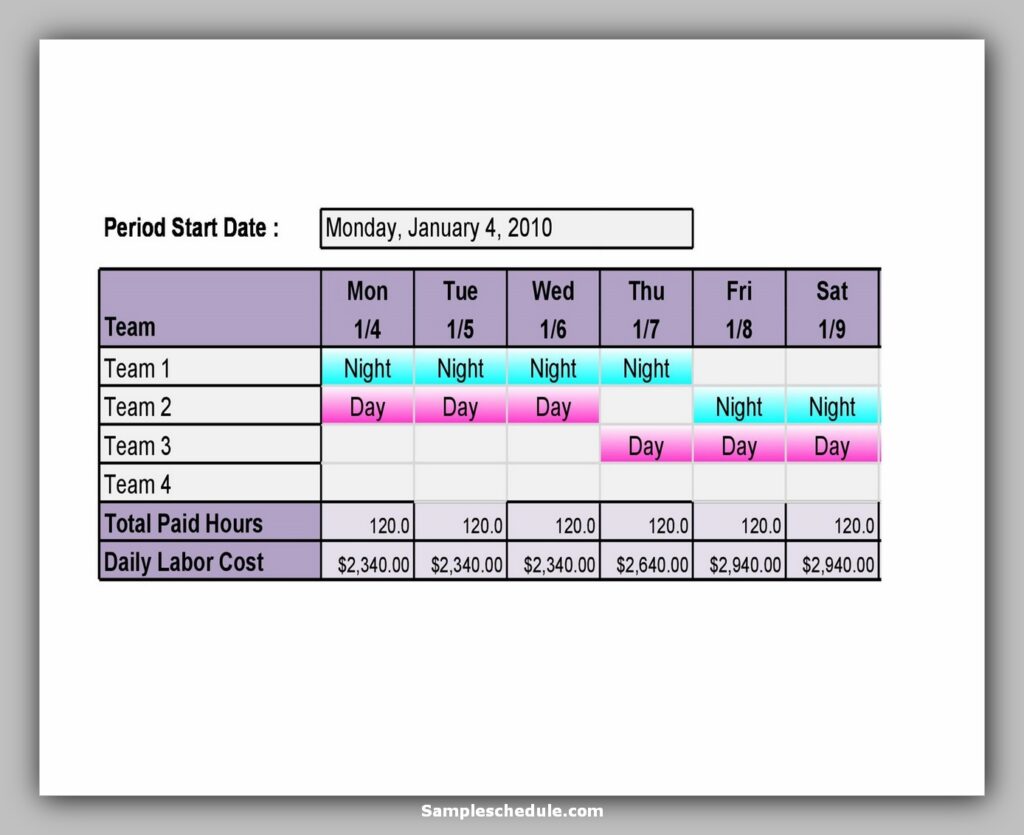

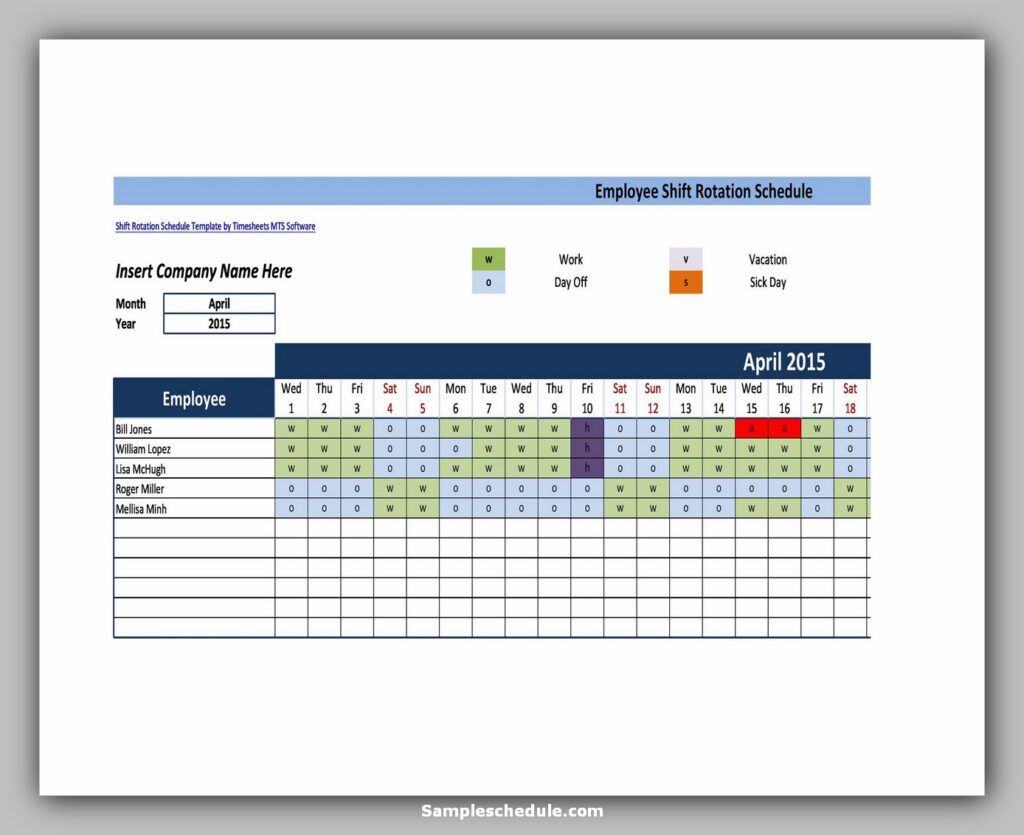

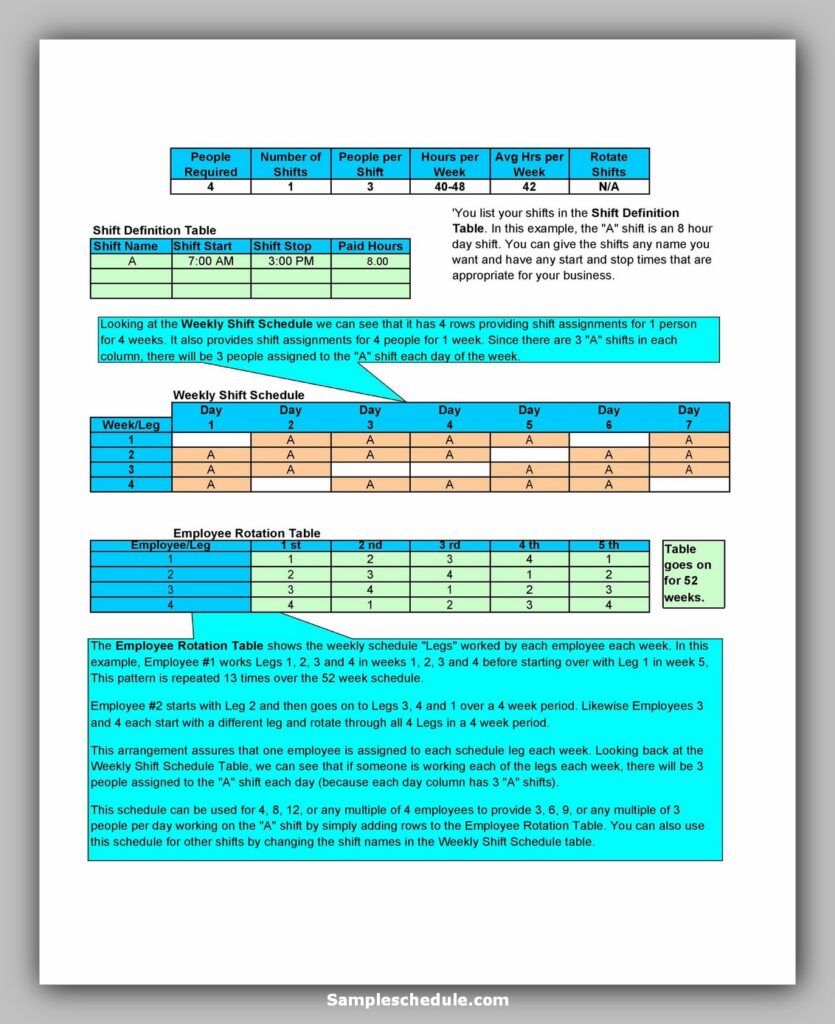

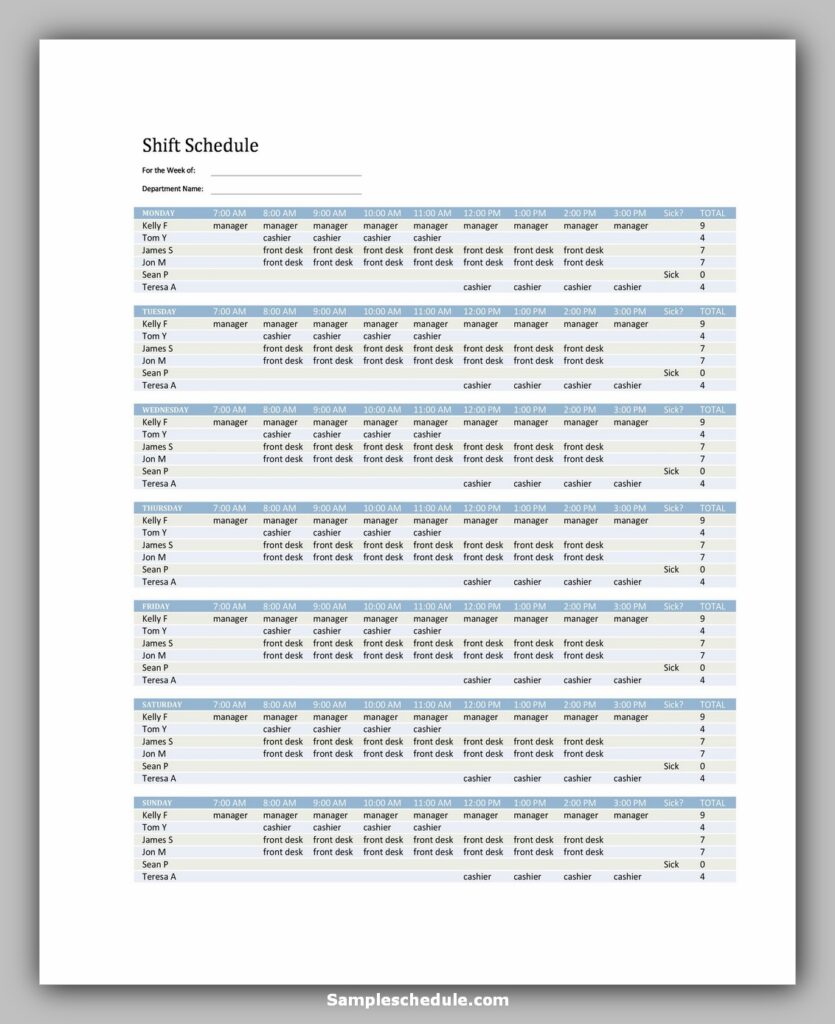

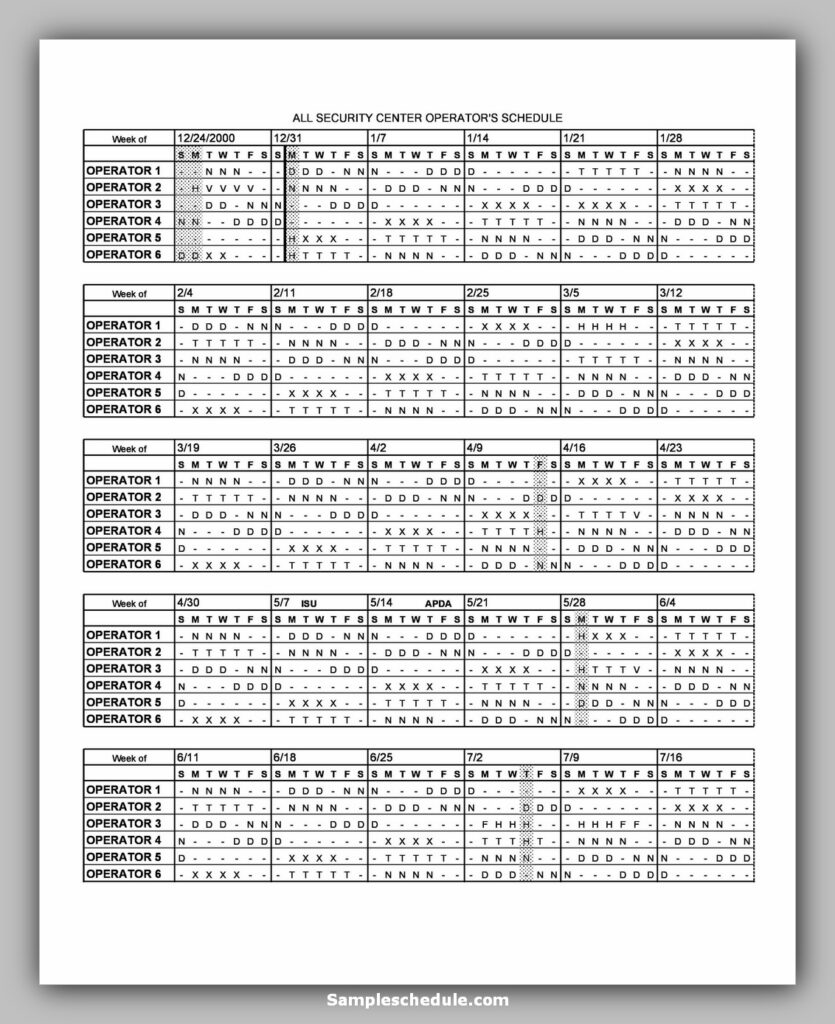

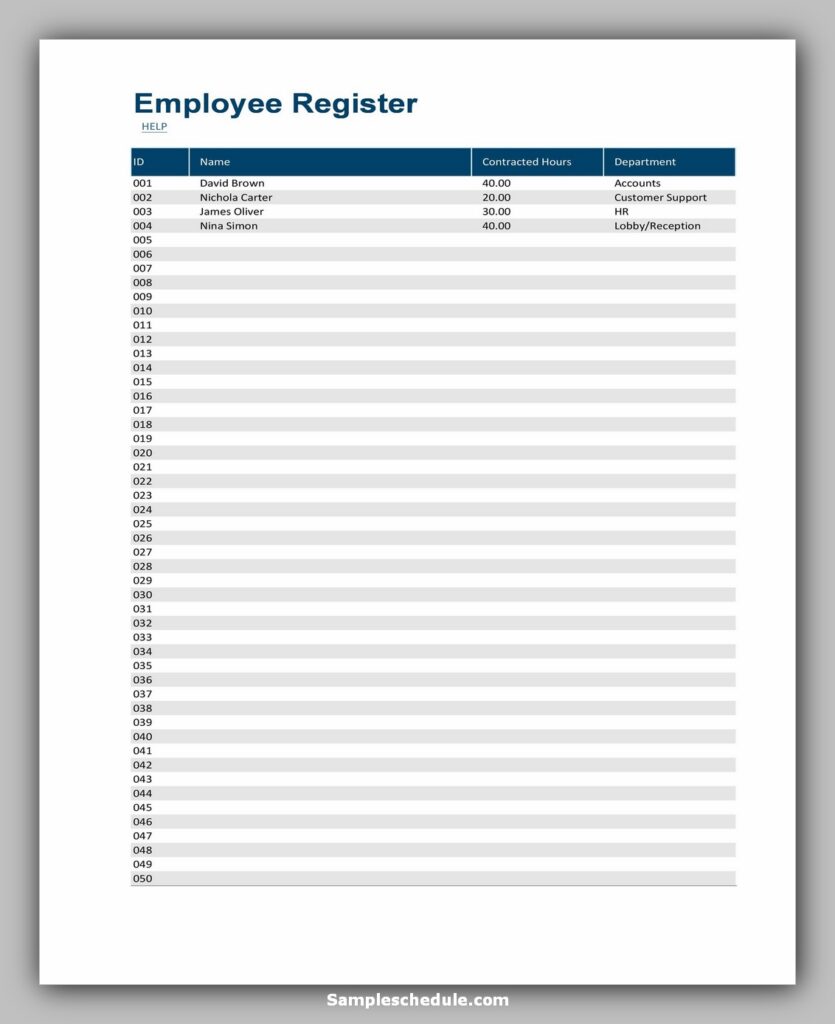

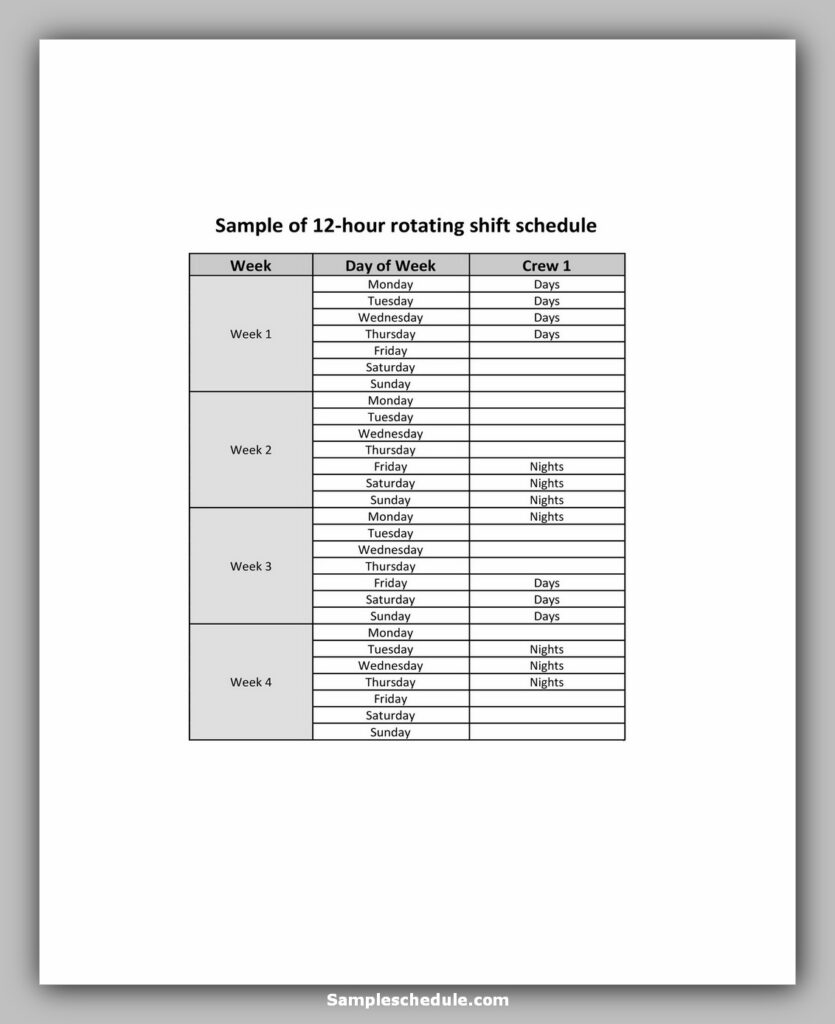

The DuPont Shift schedule contains four teams working 12-hour shifts. Each team has a name and a function. The purpose of each team is to complete a particular task, report to the main office and maintain the regular rhythm of the work pattern. The first task for each team is to identify the DuPont facility, the tasks to be performed and the shift patterns which must be followed.

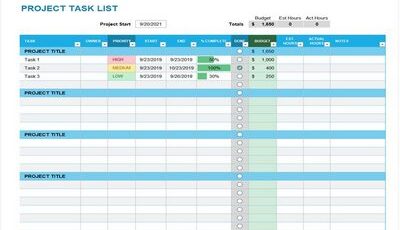

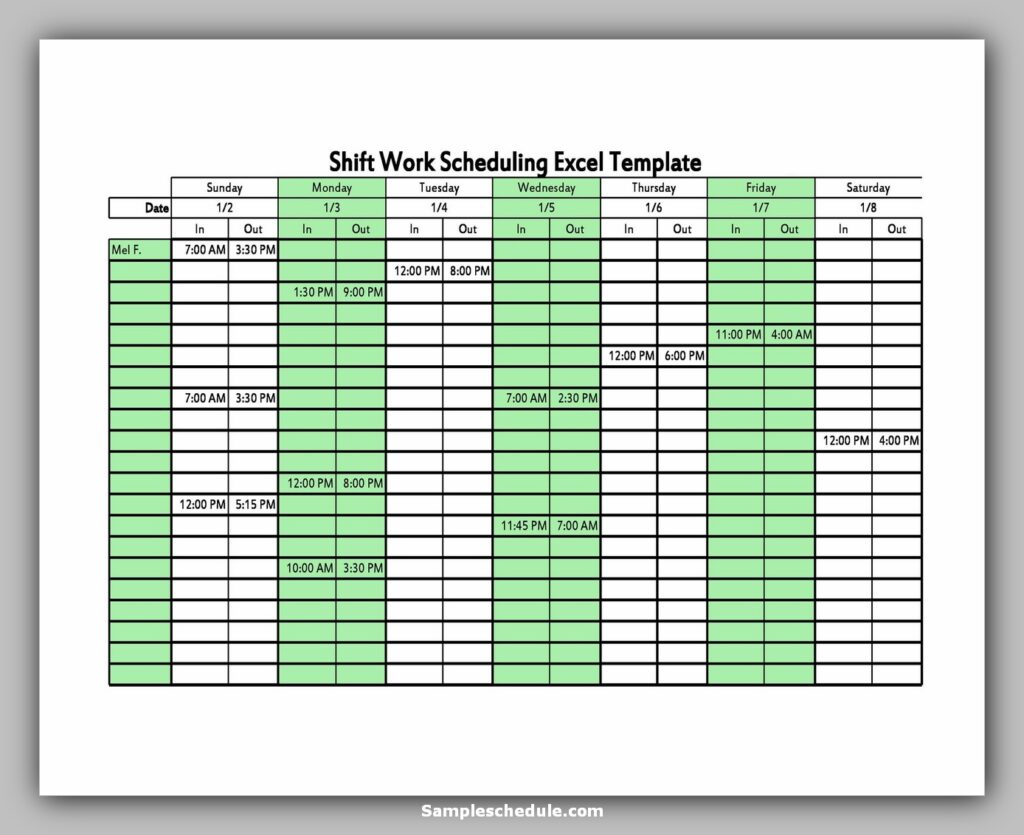

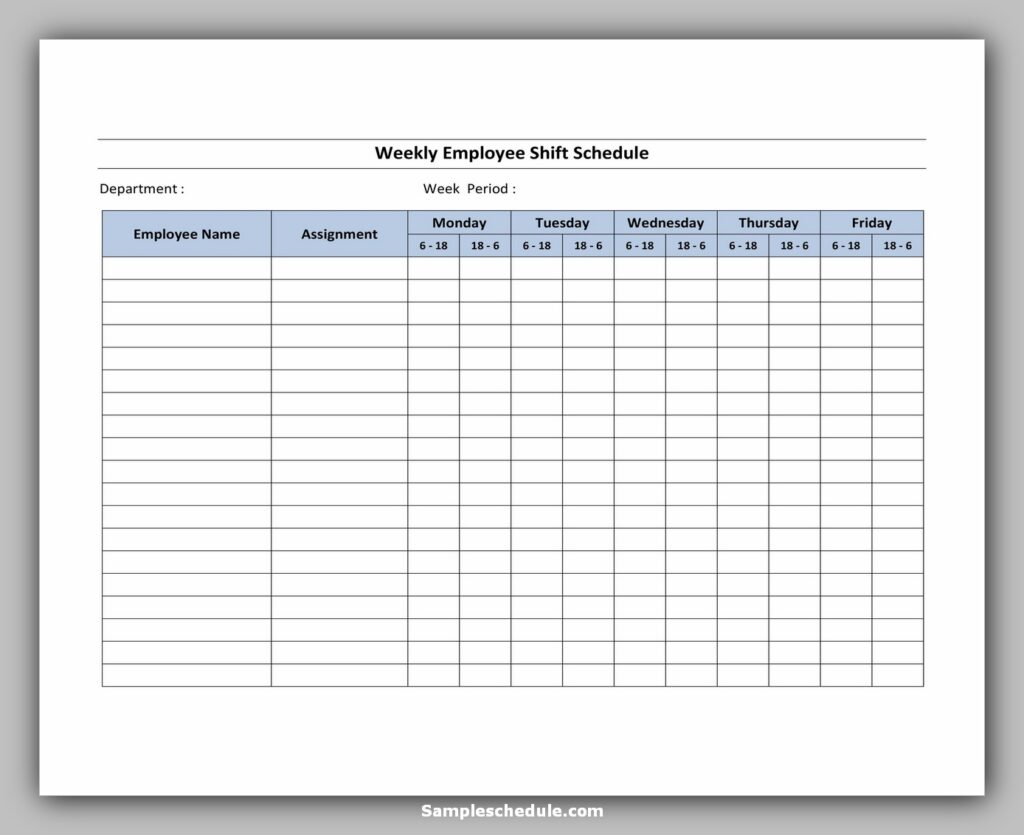

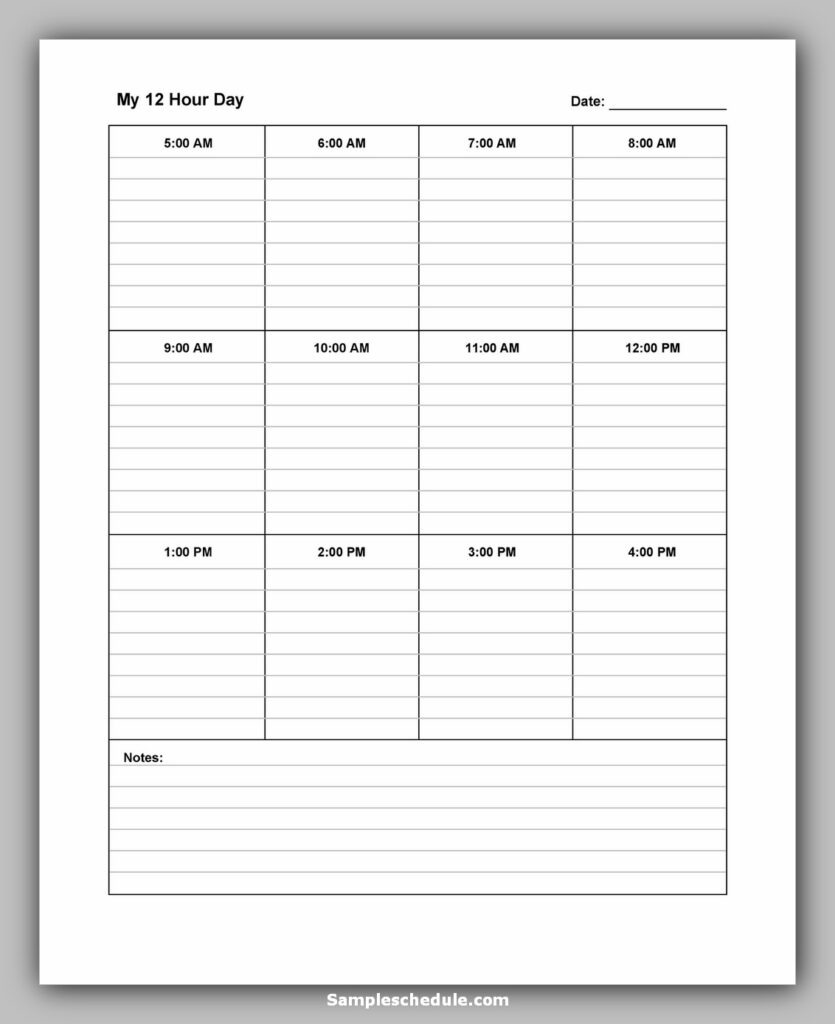

After the completion of these tasks, the teams need to generate a daily work schedule. This work schedule should include all the scheduled activities for the day and also all the scheduled overtime. The daily work schedule is generated by the system. It uses the algorithm to generate a unique pattern of the DuPont facilities. The algorithm generates the pattern according to the number of workers for each facility, the type of machines, types of personnel required and the duration of the day. All these factors are used by the system in generating a DuPont schedule.

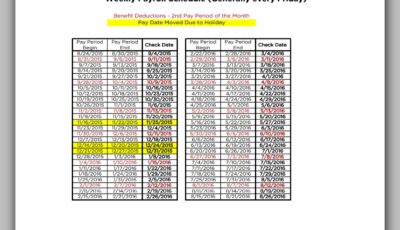

Using this method will help workers and management to make better decisions. It helps make better scheduling and allow workers and managers to adjust their schedules in accordance with external factors. The DuPont System uses three days as a rolling average for the productivity and shift scheduling. The system then creates three days average from the two remaining days.

The DuPont system uses the principle of demand and supply. The DuPont teams assign shifts according to a certain demand of work force and capacity. The demand could be for one machine or for the entire plant. On the other hand, the supply could be for two machines or for the entire plant. If the demand falls below the capacity, the DuPont teams adjust their shifts so that the daily capacity is equal to the maximum capacity.

If the demand is higher than capacity, it results in fluctuation in the DuPont shift pattern. In this case, the teams continue to work for a short period until the demand is equalized. If the demand is lower than capacity, the DuPont shifts might end up being full. But since no work can be assigned when the demand is higher than capacity, DuPont shifts tend to be longer. Most of the DuPont shifts end up lasting for 24 hours or even more than that. It is also important for DuPont teams to regularly check if the scheduled shift pattern has been completed so that the work does not get affected.

The DuPont shift work schedule is an important part of the DuPont schedule. It has helped manage the production and efficiency for decades. When using this system, employees can easily adjust the schedule in line with the changing demands of the business. For more information on the DuPont shift schedule, you can contact the DuPont Customer Service Department at any time.

DuPont Shift Schedule

DuPont Shift Schedule Template

DuPont Shift Schedule Excel

12 Hour DuPont Shift Schedule